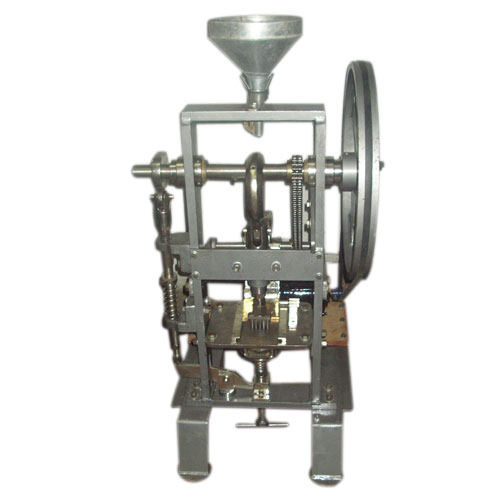

Camphor Tablet Presses

Camphor Tablet Presses Specification

- Torque

- Standard

- Phase

- Single Phase

- Shape

- Round and other custom shapes

- Diameter

- Up to 32 mm

- Product Type

- Camphor Tablet Presses

- General Use

- Tablet forming and pressing

- Material

- Mild Steel (MS), Stainless Steel (SS)

- Type

- Single Rotary Tablet Press

- Capacity

- 3000-5000 tablets/hour

- Weight (kg)

- Approx. 350 kg

- Computerized

- No

- Automatic

- Yes

- Touch Screen

- No

- Control System

- Manual/Mechanical

- Surface Treatment

- Powder Coated

- QC System

- In-process quality checking

- Tolerance

- 0.05 mm

- Voltage

- 220-240 V

- Dimension (L*W*H)

- 700 x 900 x 1500 mm

- Feature

- High efficiency, robust construction, easy operation

- Color

- Green

About Camphor Tablet Presses

Efficient Tablet Production for Diverse Applications

Designed for versatility, this single rotary tablet press accommodates camphor, detergent, salt, and other chemical tablets. With high output speeds (up to 5,000 tablets per hour) and customizable dimensions, it suits both small and large-scale production environments. The heavy-duty build ensures long-term, robust operation, while manual/mechanical controls offer straightforward use without requiring computerization.

Advanced Safety and Mobility Features

Operator safety is ensured through built-in protections such as overload prevention and an emergency stop button. The press is also highly mobile thanks to its wheel-fitted base, making it easy to reposition within the manufacturing area. The centralized manual lubrication system guarantees smooth operation and easy maintenance, supporting continuous production processes.

Superior Build Quality and Quality Control

Constructed from high-grade stainless and mild steel, the press features a durable powder-coated surface and precision tolerances (0.05 mm). Ongoing in-process quality checking helps deliver consistent products. Its compatibility with various tablet shapes, thicknesses, and materials makes it suitable for manufacturers looking for both reliability and flexibility.

FAQ's of Camphor Tablet Presses:

Q: How does the centralized manual lubrication system work in the Camphor Tablet Press?

A: The centralized manual lubrication system allows operators to apply lubricant precisely to critical moving parts through designated points. This simplifies maintenance and ensures smooth, uninterrupted operation without the complexity of fully automated lubrication systems.Q: What benefits does the overload protection system provide during tablet production?

A: The overload protection system prevents damage to the press and its motor by automatically disengaging or stopping the machine if excessive force or jamming occurs, safeguarding both equipment and operator safety during continuous use.Q: When and where should the Camphor Tablet Press be installed for optimal performance?

A: This machine is best installed in a clean, temperature-controlled manufacturing environment (5C - 40C) with a stable, level floor. Its compact footprint and wheel-fitted base allow easy placement and repositioning within tablet production lines.Q: What types of tablets can be formed using this press, and what are the size limitations?

A: The press is suitable for forming camphor, detergent, salt, and chemical tablets. It supports tablet diameters up to 32 mm, thickness between 2 and 8 mm, and can accommodate round as well as custom shapes depending on the die used.Q: How does the in-process quality checking system enhance product reliability?

A: The in-process quality checking system ensures that each tablet produced meets precise dimensional and quality standards. This system enables early detection of any deviations, maintaining consistent product quality throughout production.Q: What is the typical process for producing tablets with this machine?

A: Operators load raw material powder into the hopper, set desired tablet parameters, and start the machine. The automatic rotary mechanism compresses the material in the selected die cavity, forming tablets at 30-50 RPM. Formed tablets are then ejected and collected for packaging or further processing.Q: What are the main usage and efficiency benefits for manufacturers using this tablet press?

A: Manufacturers benefit from high tablet output (up to 5,000/hour), easy operation, and low operating noise. The robust, powder-coated construction and mobility make it a reliable, long-lasting solution for diverse tablet production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Camphor Machines Category

Camphor Making Machines

Price 87000 INR

Minimum Order Quantity : 1 Unit

Control System : Other, Mechanical/Manual Switches

Type : Other, Tabletop Rotary Camphor Machine

Computerized : No

Diameter : Die Head 2540 mm (customizable)

Camphor Making Machine

Price 87000 INR

Minimum Order Quantity : 1 Set

Control System : Other, Manual

Type : Other, Tablet/Cube

Computerized : No

Diameter : Cylinder: 1315 mm

Camphor Dies

Minimum Order Quantity : 1 Unit

Control System : Other, Manual

Type : Other, Tablet Die & Punch

Computerized : No

Diameter : Typically 6mm, 8mm, 10mm or as required

Camphor Tablet And Slab Press Machines

Control System : Manual, Other

Type : Manual mechanical press, Other

Computerized : No

Diameter : Varies depending on slab/tablet size

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese