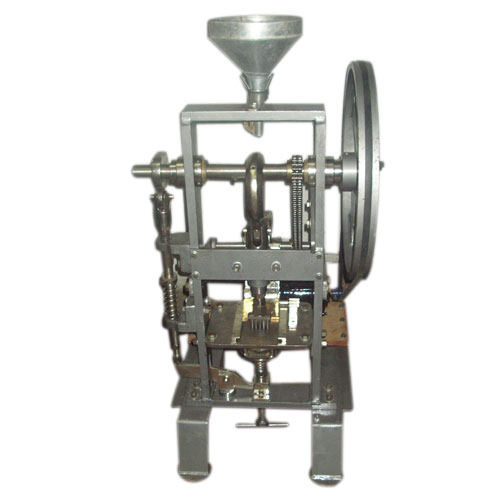

Camphor Making Machine

Camphor Making Machine Specification

- Shape

- Rectangular Base, Tablet/Cube Mould

- Phase

- Single Phase

- Torque

- High Torque Output

- Diameter

- Cylinder: 13-15 mm

- Product Type

- Camphor Making Machine

- General Use

- Manufacturing Camphor Tablets/Cubes

- Material

- Mild Steel

- Type

- Tablet/Cube

- Capacity

- 50-60 Kg/hr

- Weight (kg)

- 420 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Touch Screen

- No

- Control System

- Manual

- Surface Treatment

- Polished

- QC System

- Manual Inspection

- Tolerance

- 0.02 mm

- Drawing

- Available

- Voltage

- 220 V

- Dimension (L*W*H)

- 1100 mm x 800 mm x 1200 mm

- Feature

- Corrosion Resistant, High Productivity

- Color

- Blue & Silver

Camphor Making Machine Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 15 Sets Per Month

- Delivery Time

- 1 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- As per customer requirement

- Main Domestic Market

- All India

- Certifications

- Yes

About Camphor Making Machine

Made of mild steel or iron, this camphor making machine is well known for its fully automatic operating mode. Run by single phase power source and 1 hp motor, this camphor tablet making equipment is acknowledged as a highly productive equipment that has low operating cost. All the components of this system are made of quality tested raw materials to extend its service life and also to enhance its productivity. Offered camphor making machine is mounted on a durable base to maintain its structural stability while running at high speed.

Precision Manufacturing for Diverse Applications

This Camphor Making Machine delivers accurate and efficient tablet or cube production using its interchangeable die system. Witha 0.02 mm tolerance and polished, corrosion-resistant mild steel construction, it serves the pharmaceutical, aromatics, and religious sectors. It operates quietly at less than 75 dB, making it suitable for various work environments.

Efficient and User-Friendly Operation

Designed for semi-automatic operation, the machine uses a manual hand lever and manual QC system. Its 2 kW power consumption and 2 HP motor ensure high torque output and sustainable performance for extended production runs. Accessible spare parts and a straightforward manual control system make maintenance simple.

Robust Design and High Productivity

With a capacity to produce 50-60 kg/hr, the machines cylindrical moulds (13-15 mm diameter) and rectangular base provide stability and efficiency. Its blue and silver finish enhances durability, while precise construction supports consistent output and minimal operational stoppage.

FAQs of Camphor Making Machine:

Q: How does the hand lever operation work in the Camphor Making Machine?

A: The machine is operated manually using a hand lever, which initiates the pressing process of camphor powder into tablets or cubes. This system allows for controlled, semi-automatic operation and is suitable for both small and medium-scale production.Q: What are the key benefits of using this Camphor Making Machine for manufacturers?

A: Key benefits include high productivity (up to 60 kg/hr), consistent tablet/cube formation due to precision die sets, low noise levels, durable corrosion-resistant construction, and easy access to spare parts for reliable maintenance.Q: When should the interchangeable die set be used or replaced?

A: Interchangeable die sets should be used when different tablet or cube sizes are needed, or replaced if wear or damage affects product quality. They are designed for quick changes to maximize operational flexibility and productivity.Q: Where is this Camphor Making Machine commonly used?

A: This machine is widely used in India, particularly by manufacturers and suppliers in the pharmaceutical, religious, and aromatic industries who require bulk camphor tablet or cube production with reliable equipment.Q: What is the general process for manufacturing camphor tablets or cubes with this machine?

A: The process involves loading camphor powder into the hopper, selecting the appropriate die set, and using the hand lever to compress the powder into tablets/cubes. Each production cycle takes about one minute, ensuring efficient output.Q: How accessible are the spare parts for this machine?

A: Spare parts are designed to be easily accessible, allowing manufacturers and operators to perform routine maintenance and repairs promptly, ensuring continued high performance and minimal downtime.Q: What makes this machine suitable for the pharmaceutical and aromatic industries?

A: Its precise manufacturing tolerance, high productivity, corrosion-resistant surface, and manual inspection system make it ideal for producing standardized, high-quality camphor products required in sensitive applications such as pharmaceuticals and aromatics.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Camphor Machines Category

Camphor Making Machines

Price 87000 INR

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Approx 915 mm x 610 mm x 1219 mm

Diameter : Die Head 2540 mm (customizable)

Type : Other, Tabletop Rotary Camphor Machine

Surface Treatment : Other, Paint Coated / Polished Steel

Camphor Dies

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : Varies as per model and customization

Diameter : Typically 6mm, 8mm, 10mm or as required

Type : Other, Tablet Die & Punch

Surface Treatment : Other, Polished and rustresistant coating

Camphor Tablet Presses

Dimension (L*W*H) : 700 x 900 x 1500 mm

Diameter : Up to 32 mm

Type : Other, Single Rotary Tablet Press

Surface Treatment : Other, Powder Coated

Camphor Tablet And Slab Press Machines

Dimension (L*W*H) : Standard dimensions available on request

Diameter : Varies depending on slab/tablet size

Type : Manual mechanical press, Other

Surface Treatment : Other, Polished metal surface

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese